DEFINE

| MM | : 53535435 |

| Product Name | : BTL DETTOL ID 250ML DT 3092UV |

| Customer | : Reckitt Benckiser Indenesia |

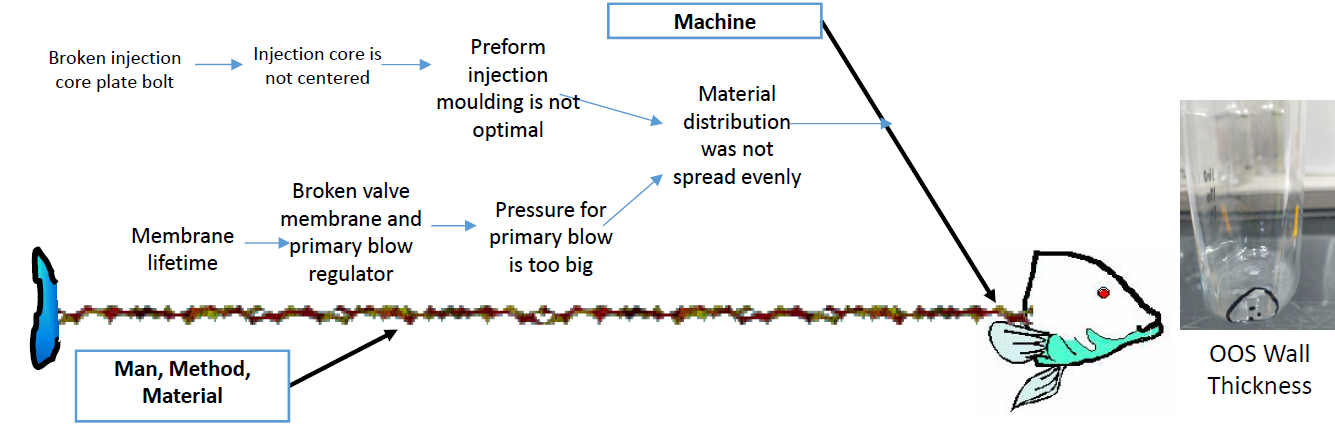

| Problem | : OOS Wall Thinckness |

| Problem Occur | : Line Customer |

| Reported By | : Imam & Fais |

| Batch | : 23213214 |

| Complaint Date | : 22/01/2024 |

| SNCR No | : RN-23324-43453 |

| Status | : Complaint |

DETAIL DEFECT

TRACEABILITY

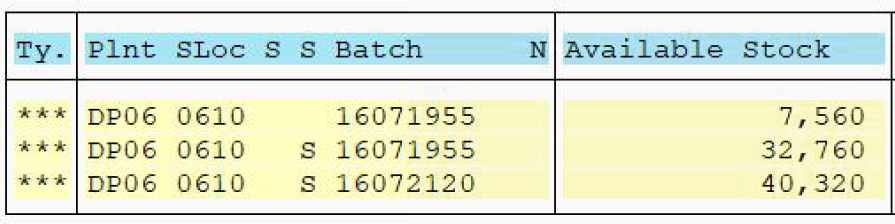

Production History :

BTL DETTOL ID FHW 250ML DT 3095596 UVI Batch 16071955

Produced at Machine ASB 12

| Production Date | : 03-10.01.2024 |

| Total Production | : 80.640 pcs |

| Stock | : 40,320 |

Detail Delivery :

| Delivery Order | DO Date | Quantity(Pcs) |

|---|---|---|

| 26193938 | 11/01/2024 | 40.320 |

| Total Quantity | 40.320 | |